FGIS 936 Sampler Condition Report

Reporting and Recordkeeping Requirements (US Grain Standards Act and Agricultural Marketing Act of 1946)

FGIS 936 1.21 (508).xlsx

OMB: 0581-0309

Document [xlsx]

Download: xlsx | pdf

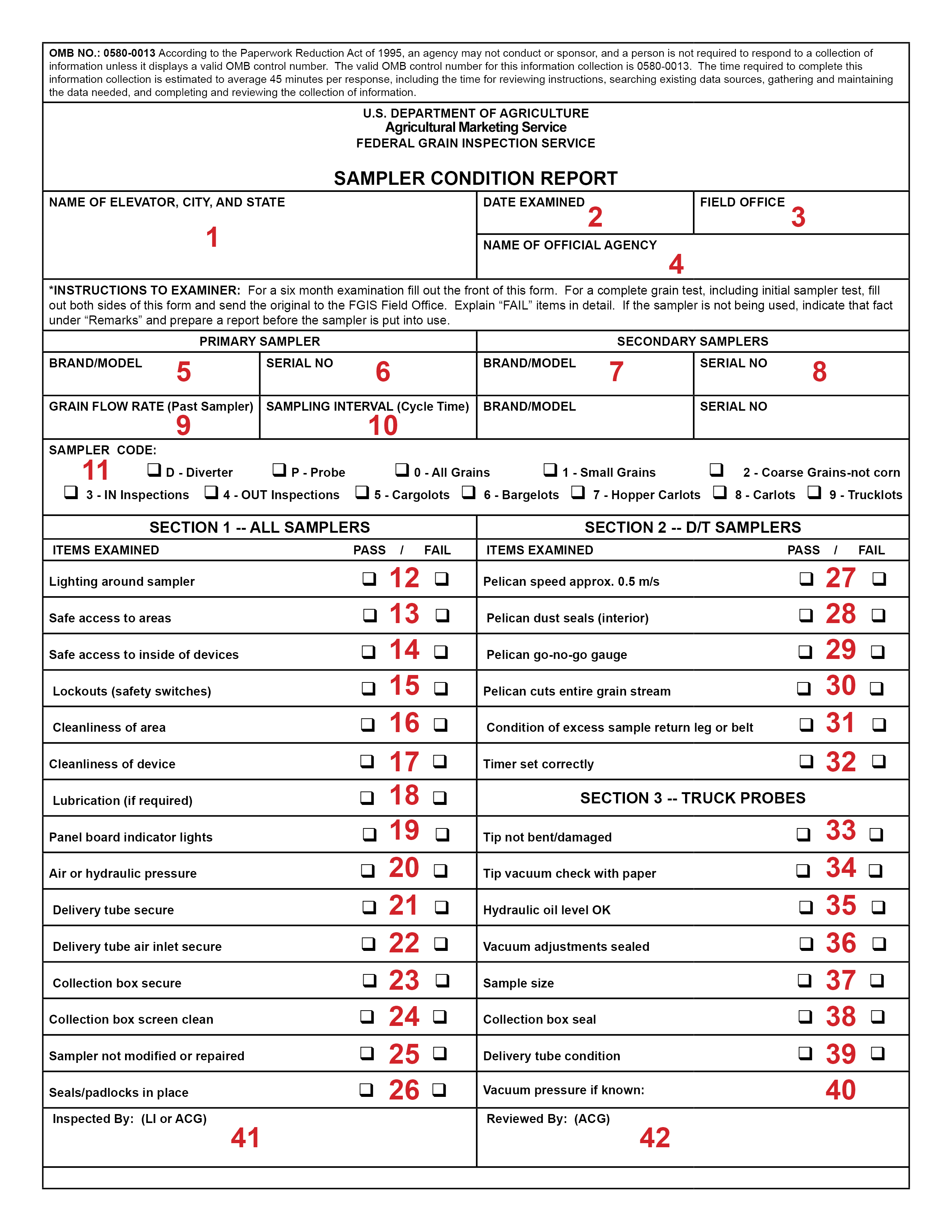

Front Instructions

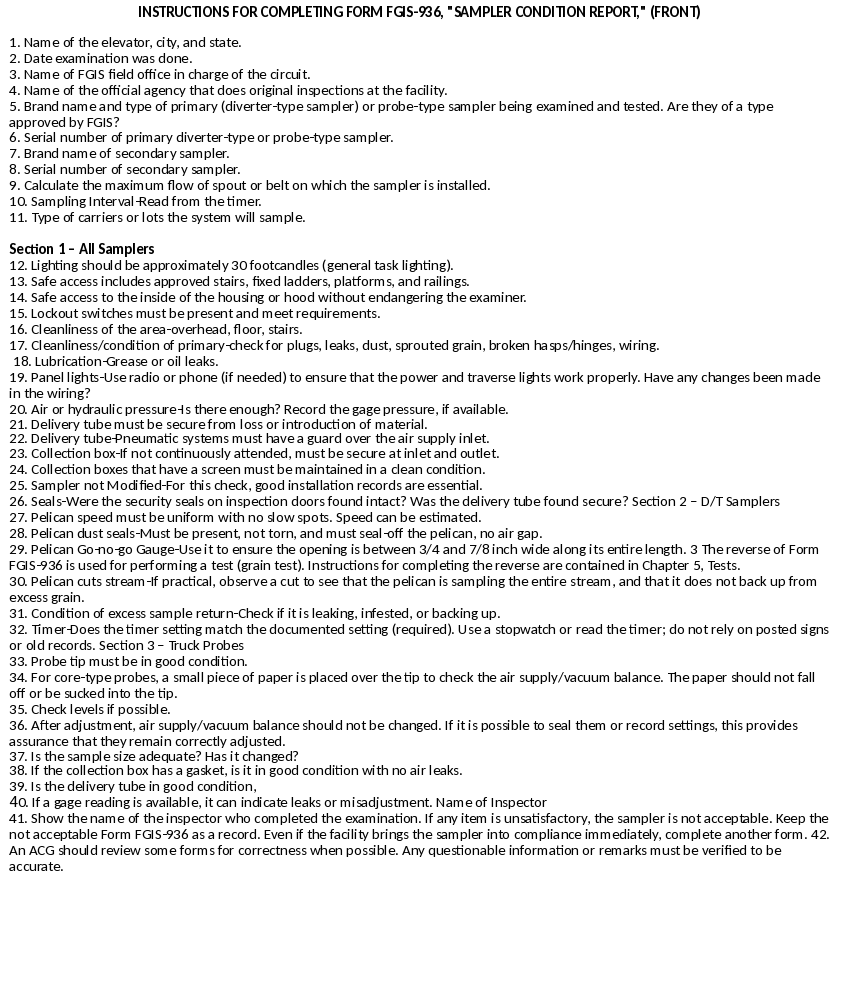

Back

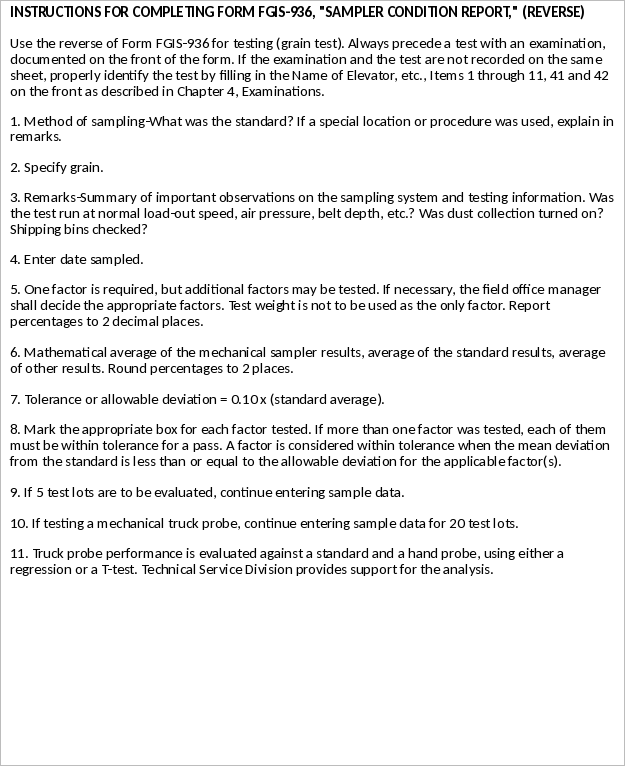

Back Instructions

Overview

FrontFront Instructions

Back

Back Instructions

Sheet 1: Front

| OMB NO.: 0581-0309 (See reverse) | |||||||||||

| U.S. DEPARTMENT OF AGRICULTURE | |||||||||||

| AGRICULTURAL MARKETING SERVICE | |||||||||||

| FEDERAL GRAIN INSPECTION SERVICE | |||||||||||

| SAMPLER CONDITION REPORT | |||||||||||

| NAME OF ELEVATOR, CITY, AND STATE | DATE EXAMINED | FIELD OFFICE | |||||||||

| NAME OF OFFICIAL AGENCY | |||||||||||

| PRIMARY SAMPLER | SECONDARY SAMPLERS | ||||||||||

| BRAND/MODEL | SERIAL NO. | BRAND/MODEL | SERIAL NO. | ||||||||

| GRAIN FLOW RATE (Past Sampler) | SAMPLING INTERVAL (Cycle Time) | BRAND/MODEL | SERIAL NO. | ||||||||

| SECTION 1 -- ALL SAMPLERS | SECTION 2 -- D/T SAMPLERS | ||||||||||

| ITEMS EXAMINED PASS / FAIL | ITEMS EXAMINED | PASS / FAIL | |||||||||

| Lighting around sampler | Pelican speed approx. 0.5 m/s | ||||||||||

| Safe access to areas | Pelican dust seals (interior) | ||||||||||

| Safe access to inside of devices | Pelican go-no-go gauge | ||||||||||

| Lockouts (safety switches) | Pelican cuts entire grain stream | ||||||||||

| Cleanliness of area | Condition of excess sample return leg or belt | ||||||||||

| Cleanliness of device | |||||||||||

| Lubrication (if required) | SECTION 3 -- TRUCK PROBES | ||||||||||

| Panel board indicator lights | ITEMS EXAMINED PASS / FAIL | ||||||||||

| Air or hydraulic pressure | Tip not bent/damaged | ||||||||||

| Delivery tube secure | Tip vacuum check with paper | ||||||||||

| Delivery tube air inlet secure | Hydraulic oil level OK | ||||||||||

| Collection box secure | Vacuum adjustments sealed | ||||||||||

| Collection box screen clean | Sample size | ||||||||||

| Sampler not modified or repaired | Collection box seal | ||||||||||

| Seals/padlocks in place | Delivery tube condition | ||||||||||

| Inspected By: (LI or ACG) | Vacuum pressure if known: | ||||||||||

| Reviewed By: (ACG) | |||||||||||

| Form FGIS-936 (01/21) Previous editions are obsolete. Expires XX-XX | |||||||||||

Sheet 2: Front Instructions

|

|

|

|

Sheet 3: Back

|

|||||||||||

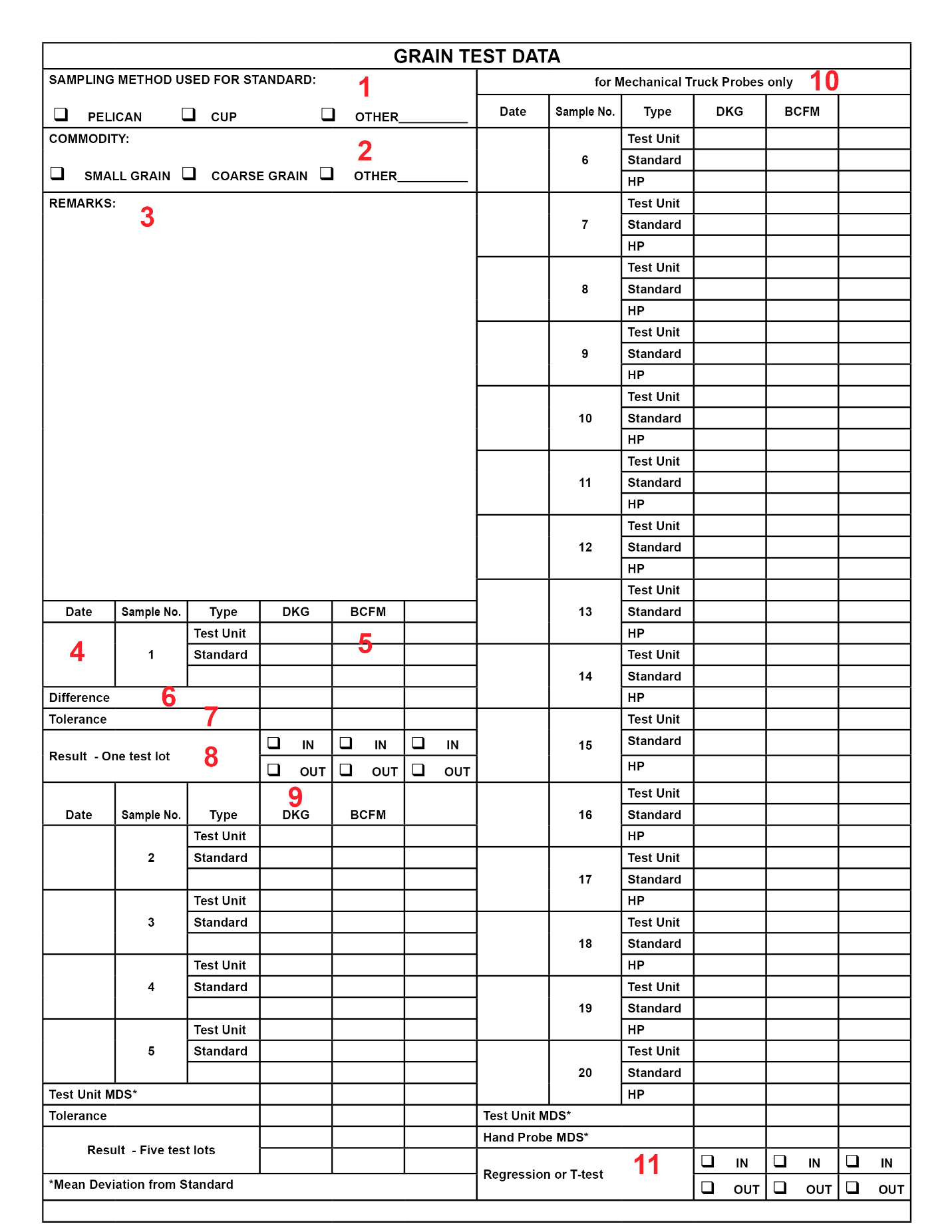

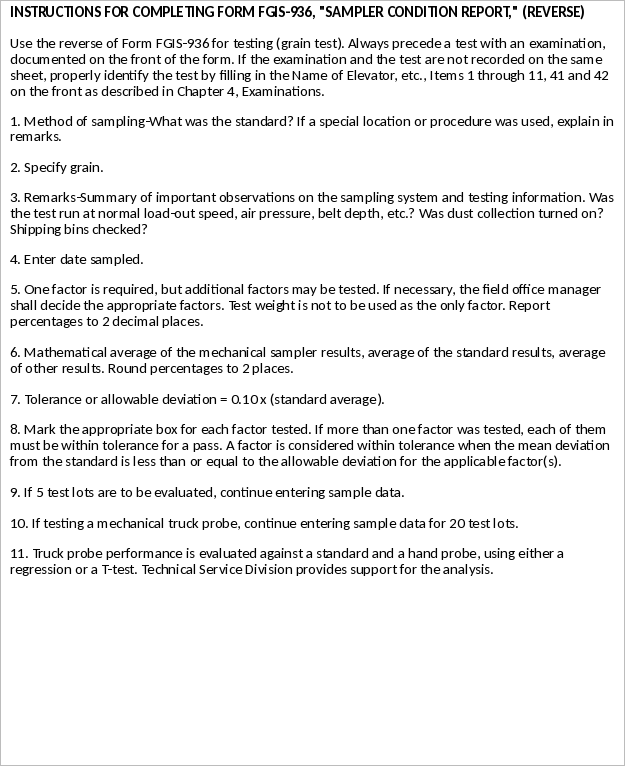

| GRAIN TEST DATA | |||||||||||

| SAMPLING METHOD USED FOR STANDARD: | for Mechanical Truck Probes only | ||||||||||

| ________ | Date | Sample No. | Type | DKG | BCFM | ||||||

| COMMODITY: | Test Unit | ||||||||||

| ________ | 6 | Standard | |||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 7 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 8 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 9 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 10 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 11 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 12 | Standard | ||||||||||

| HP | |||||||||||

| Date | Sample No. | Type | DKG | BCFM | Test Unit | ||||||

| Test Unit | 13 | Standard | |||||||||

| 1 | Standard | HP | |||||||||

| Test Unit | |||||||||||

| Difference | 14 | Standard | |||||||||

| Tolerance | HP | ||||||||||

| Result - One test lot | Test Unit | ||||||||||

| 15 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| Date | Sample No. | Type | DKG | BCFM | 16 | Standard | |||||

| Test Unit | HP | ||||||||||

| 2 | Standard | Test Unit | |||||||||

| 17 | Standard | ||||||||||

| Test Unit | HP | ||||||||||

| 3 | Standard | Test Unit | |||||||||

| 18 | Standard | ||||||||||

| Test Unit | HP | ||||||||||

| 4 | Standard | Test Unit | |||||||||

| 19 | Standard | ||||||||||

| Test Unit | HP | ||||||||||

| 5 | Standard | Test Unit | |||||||||

| 20 | Standard | ||||||||||

| Test Unit MDS* | HP | ||||||||||

| Tolerance | Test Unit MDS* | ||||||||||

| Result - Five test lots | Hand Probe MDS* | ||||||||||

| Regression or T-test | |||||||||||

| *Mean Deviation from Standard | |||||||||||

| Form FGIS-936 Form FGIS-936 (01/21) Previous editions are obsolete. Expires XX-XX | |||||||||||

Sheet 4: Back Instructions

|

|

| File Type | application/vnd.openxmlformats-officedocument.spreadsheetml.sheet |

| File Modified | 0000-00-00 |

| File Created | 0000-00-00 |

© 2025 OMB.report | Privacy Policy