Regulatory Text

2457.05_Recordkeeping_Reporting.docx

NESHAP for Group IV Polymers and Resins (40 CFR part 63, subpart JJJ) (Renewal)

Regulatory Text

OMB: 2060-0682

§ 63.7 Performance testing requirements.

(f) Use of an alternative test method —

(1) General. Until authorized to use an intermediate or major change or alternative to a test method, the owner or operator of an affected source remains subject to the requirements of this section and the relevant standard.

(2) The owner or operator of an affected source required to do performance testing by a relevant standard may use an alternative test method from that specified in the standard provided that the owner or operator—

(i) Notifies the Administrator of his or her intention to use an alternative test method at least 60 days before the performance test is scheduled to begin;

(ii) Uses Method 301 in appendix A of this part to validate the alternative test method. This may include the use of specific procedures of Method 301 if use of such procedures are sufficient to validate the alternative test method; and

(iii) Submits the results of the Method 301 validation process along with the notification of intention and the justification for not using the specified test method. The owner or operator may submit the information required in this paragraph well in advance of the deadline specified in paragraph (f)(2)(i) of this section to ensure a timely review by the Administrator in order to meet the performance test date specified in this section or the relevant standard.

(3) The Administrator will determine whether the owner or operator's validation of the proposed alternative test method is adequate and issue an approval or disapproval of the alternative test method. If the owner or operator intends to demonstrate compliance by using an alternative to any test method specified in the relevant standard, the owner or operator is authorized to conduct the performance test using an alternative test method after the Administrator approves the use of the alternative method. However, the owner or operator is authorized to conduct the performance test using an alternative method in the absence of notification of approval/disapproval 45 days after submission of the request to use an alternative method and the request satisfies the requirements in paragraph (f)(2) of this section. The owner or operator is authorized to conduct the performance test within 60 calendar days after he/she is authorized to demonstrate compliance using an alternative test method. Notwithstanding the requirements in the preceding three sentences, the owner or operator may proceed to conduct the performance test as required in this section (without the Administrator's prior approval of the site-specific test plan) if he/she subsequently chooses to use the specified testing and monitoring methods instead of an alternative.

(4) If the Administrator finds reasonable grounds to dispute the results obtained by an alternative test method for the purposes of demonstrating compliance with a relevant standard, the Administrator may require the use of a test method specified in a relevant standard.

(5) If the owner or operator uses an alternative test method for an affected source during a required performance test, the owner or operator of such source shall continue to use the alternative test method for subsequent performance tests at that affected source until he or she receives approval from the Administrator to use another test method as allowed under § 63.7(f).

(6) Neither the validation and approval process nor the failure to validate an alternative test method shall abrogate the owner or operator's responsibility to comply with the requirements of this part.

§ 63.9 Notification requirements.

(b) Initial notifications.

(1)

(i) The requirements of this paragraph apply to the owner or operator of an affected source when such source becomes subject to a relevant standard.

(ii) If an area source subsequently becomes a major source that is subject to the emission standard or other requirement, such source shall be subject to the notification requirements of this section. Area sources previously subject to major source requirements that become major sources again are also subject to the notification requirements of this paragraph and must submit the notification according to the requirements of paragraph (k) of this section.

(iii) Affected sources that are required under this paragraph to submit an initial notification may use the application for approval of construction or reconstruction under § 63.5(d) of this subpart, if relevant, to fulfill the initial notification requirements of this paragraph.

(2) The owner or operator of an affected source that has an initial startup before the effective date of a relevant standard under this part shall notify the Administrator in writing that the source is subject to the relevant standard. The notification, which shall be submitted not later than 120 calendar days after the effective date of the relevant standard (or within 120 calendar days after the source becomes subject to the relevant standard), shall provide the following information:

(i) The name and address of the owner or operator;

(ii) The address (i.e., physical location) of the affected source;

(iii) An identification of the relevant standard, or other requirement, that is the basis of the notification and the source's compliance date;

(iv) A brief description of the nature, size, design, and method of operation of the source and an identification of the types of emission points within the affected source subject to the relevant standard and types of hazardous air pollutants emitted; and

(v) A statement of whether the affected source is a major source or an area source.

(3) [Reserved]

(4) The owner or operator of a new or reconstructed major affected source for which an application for approval of construction or reconstruction is required under § 63.5(d) must provide the following information in writing to the Administrator:

(i) A notification of intention to construct a new major-emitting affected source, reconstruct a major-emitting affected source, or reconstruct a major source such that the source becomes a major-emitting affected source with the application for approval of construction or reconstruction as specified in § 63.5(d)(1)(i); and

(ii)-(iv) [Reserved]

(v) A notification of the actual date of startup of the source, delivered or postmarked within 15 calendar days after that date.

(5) The owner or operator of a new or reconstructed affected source for which an application for approval of construction or reconstruction is not required under § 63.5(d) must provide the following information in writing to the Administrator:

(i) A notification of intention to construct a new affected source, reconstruct an affected source, or reconstruct a source such that the source becomes an affected source, and

(ii) A notification of the actual date of startup of the source, delivered or postmarked within 15 calendar days after that date.

(iii) Unless the owner or operator has requested and received prior permission from the Administrator to submit less than the information in § 63.5(d), the notification must include the information required on the application for approval of construction or reconstruction as specified in § 63.5(d)(1)(i).

(c) Request for extension of compliance. If the owner or operator of an affected source cannot comply with a relevant standard by the applicable compliance date for that source, or if the owner or operator has installed BACT or technology to meet LAER consistent with § 63.6(i)(5) of this subpart, he/she may submit to the Administrator (or the State with an approved permit program) a request for an extension of compliance as specified in § 63.6(i)(4) through § 63.6(i)(6).

(d) Notification that source is subject to special compliance requirements. An owner or operator of a new source that is subject to special compliance requirements as specified in § 63.6(b)(3) and § 63.6(b)(4) shall notify the Administrator of his/her compliance obligations not later than the notification dates established in paragraph (b) of this section for new sources that are not subject to the special provisions.

(j) Change in information already provided. Any change in the information already provided under this section shall be provided to the Administrator within 15 calendar days after the change. The owner or operator of a major source that reclassifies to area source status is also subject to the notification requirements of this paragraph. The owner or operator may submit the application for reclassification with the regulatory authority (e.g., permit application) according to paragraph (k) of this section to fulfill the requirements of this paragraph, but the information required in paragraphs (j)(1) through (4) of this section must be included. A source which reclassified after January 25, 2018, and before January 19, 2021, and has not yet provided the notification of a change in information is required to provide such notification no later than February 2, 2021, according to the requirements of paragraph (k) of this section. Beginning January 19, 2021, the owner or operator of a major source that reclassifies to area source status must submit the notification according to the requirements of paragraph (k) of this section. A notification of reclassification must contain the following information:

(1) The name and address of the owner or operator;

(2) The address (i.e., physical location) of the affected source;

(3) An identification of the standard being reclassified from and to (if applicable); and

(4) Date of effectiveness of the reclassification.

§ 63.10 Recordkeeping and reporting requirements.

(d) General reporting requirements.

(4) Progress reports. The owner or operator of an affected source who is required to submit progress reports as a condition of receiving an extension of compliance under § 63.6(i) shall submit such reports to the Administrator (or the State with an approved permit program) by the dates specified in the written extension of compliance.

§ 63.182 Reporting requirements.

(a) Each owner or operator of a source subject to this subpart shall submit the reports listed in paragraphs (a)(1) through (a)(5) of this section. Owners or operators requesting an extension of compliance shall also submit the report listed in paragraph (a)(6) of this section.

(3) Periodic Reports described in paragraph (d) of this section.

(d) The owner or operator of a source subject to this subpart shall submit Periodic Reports. On and after July 15, 2027 or once the reporting template for this subpart has been available on the CEDRI website for 1 year, whichever date is later, owners and operators must submit all subsequent reports following the procedure specified in § 63.9(k), except any medium submitted through mail must be sent to the attention of the Hazardous Organic Chemical Manufacturing Sector Lead. Owners and operators must use the appropriate electronic report template on the CEDRI website (https://www.epa.gov/electronic-reporting-air-emissions/cedri) for this subpart. The date report templates become available will be listed on the CEDRI website. Unless the Administrator or delegated state agency or other authority has approved a different schedule for submission of reports under § 63.9(i) and § 63.10(a), the report must be submitted by the deadline specified in this subpart, regardless of the method in which the report is submitted. All Periodic Reports must include the following general information: company name, address (including county), and beginning and ending dates of the reporting period.

(1) A report containing the information in paragraphs (d)(2), (d)(3), and (d)(4) of this section shall be submitted semiannually starting 6 months after the Notification of Compliance Status, as required in paragraph (c) of this section. The first periodic report shall cover the first 6 months after the compliance date specified in § 63.100(k)(3) of subpart F. Each subsequent periodic report shall cover the 6 month period following the preceding period.

(2) For each process unit complying with the provisions of § 63.163 through § 63.174, the summary information listed in paragraphs (d)(2)(i) through (xix) of this paragraph for each monitoring period during the 6-month period.

(i) The number of valves for which leaks were detected as described in § 63.168(b) of this subpart, the percent leakers, and the total number of valves monitored;

(ii) The number of valves for which leaks were not repaired as required in § 63.168(f) of this subpart, identifying the number of those that are determined nonrepairable;

(iii) The number of pumps for which leaks were detected as described in § 63.163(b) of this subpart, the percent leakers, and the total number of pumps monitored;

(iv) The number of pumps for which leaks were not repaired as required in § 63.163(c) of this subpart;

(v) The number of compressors for which leaks were detected as described in § 63.164(f) of this subpart;

(vi) The number of compressors for which leaks were not repaired as required in § 63.164(g) of this subpart;

(vii) The number of agitators for which leaks were detected as described in § 63.173(a) and (b) of this subpart;

(viii) The number of agitators for which leaks were not repaired as required in § 63.173(c) of this subpart;

(ix) The number of connectors for which leaks were detected as described in § 63.174(a) of this subpart, the percent of connectors leaking, and the total number of connectors monitored;

(x) [Reserved]

(xi) The number of connectors for which leaks were not repaired as required in § 63.174(d) of this subpart, identifying the number of those that are determined nonrepairable;

(xii) [Reserved]

(xiii) The facts that explain any delay of repairs and, where appropriate, why a process unit shutdown was technically infeasible.

(xiv) The results of all monitoring to show compliance with §§ 63.164(i), 63.165(a), and 63.172(f) of this subpart conducted within the semiannual reporting period.

(xv) If applicable, the initiation of a monthly monitoring program under § 63.168(d)(1)(i) of this subpart, or a quality improvement program under either §§ 63.175 or 63.176 of this subpart.

(xvi) If applicable, notification of a change in connector monitoring alternatives as described in § 63.174(c)(1) of this subpart.

(xvii) If applicable, the compliance option that has been selected under § 63.172(n).

(xviii) Compliance reports for pressure relief devices subject to the requirements § 63.165(e) must include the information specified in paragraphs (d)(2)(xviii)(A) through (C) of this section.

(A) For pressure relief devices in organic HAP gas or vapor service, pursuant to § 63.165(e)(1), report the instrument readings and dates for all readings of 500 ppm or greater.

(B) For pressure relief devices in organic HAP gas or vapor service subject to § 63.165(e)(2), report the instrument readings and dates of instrument monitoring conducted.

(C) For pressure relief devices in organic HAP service subject to § 63.165(e)(3), report each pressure release to the atmosphere, including pressure relief device identification name or number, the start date, start time, and duration (in minutes) of the pressure release; an estimate of the mass quantity in pounds of each organic HAP released; the results of any root cause analysis and corrective action analysis completed during the reporting period, including the corrective actions implemented during the reporting period; and, if applicable, the implementation schedule for planned corrective actions to be implemented subsequent to the reporting period.

(xix) For each source as defined in § 63.101, and for each source as defined in § 63.191, beginning no later than the compliance dates specified in § 63.100(k)(10), the owner or operator must comply with this paragraph in addition to the requirements in paragraphs (d)(2)(i) through (d)(2)(xviii) of this section. For bypass lines subject to the requirements in § 63.172(j), the Periodic Report must include the start date, start time, duration in hours, estimate of the volume of gas in standard cubic feet, the concentration of organic HAP in the gas in parts per million by volume and the resulting mass emissions of organic HAP in pounds that bypass a control device. For periods when the flow indicator is not operating, report the start date, start time, and duration in hours.

(3) For owners or operators electing to meet the requirements of § 63.178(b) of this subpart, the report shall include the information listed in paragraphs (i) through (v) of this paragraph for each process unit.

(i) Batch product process equipment train identification;

(ii) The number of pressure tests conducted;

(iii) The number of pressure tests where the equipment train failed the pressure test;

(iv) The facts that explain any delay of repairs; and

(v) The results of all monitoring to determine compliance with § 63.172(f) of this subpart.

(4) The information listed in paragraph (c) of this section for the Notification of Compliance Status for process units with later compliance dates. Any revisions to items reported in earlier Notification of Compliance Status, if the method of compliance has changed since the last report.

§ 63.1310 Applicability and designation of affected sources.

(b) TPPUs without organic HAP. The owner or operator of a TPPU that is part of an affected source, as defined in paragraph (a) of this section, but that does not use or manufacture any organic HAP shall comply with the requirements of either paragraph (b)(1) or (b)(2) of this section. Such a TPPU is not subject to any other provisions of this subpart and is not required to comply with the provisions of subpart A of this part.

(1) Retain information, data, and analyses used to document the basis for the determination that the TPPU does not use or manufacture any organic HAP. Types of information that could document this determination include, but are not limited to, records of chemicals purchased for the process, analyses of process stream composition, engineering calculations, or process knowledge.

(2) When requested by the Administrator, demonstrate that the TPPU does not use or manufacture any organic HAP.

§ 63.1315 Continuous process vents provisions.

(a) For each continuous process vent located at an affected source, the owner or operator shall comply with the requirements of §§ 63.113 through 63.118, with the differences noted in paragraphs (a)(1) through (19) of this section for the purposes of this subpart, except as provided in paragraphs (b) through (e) of this section.

(1) When the term “process vent” is used in §§ 63.113 through 63.118, the term “continuous process vent,” and the definition of this term in § 63.1312 shall apply for the purposes of this subpart.

(2) When the term “Group 1 process vent” is used in §§ 63.113 through 63.118, the term “Group 1 continuous process vent,” and the definition of this term in § 63.1312 shall apply for the purposes of this subpart.

(3) When the term “Group 2 process vent” is used in §§ 63.113 through 63.118, the term “Group 2 continuous process vent,” and the definition of this term in § 63.1312 shall apply for the purposes of this subpart.

(4) When December 31, 1992 is referred to in § 63.113, apply the date March 29, 1995, for the purposes of this subpart.

(5) When § 63.151(f), alternative monitoring parameters, and § 63.152(e), submission of an operating permit, are referred to in §§ 63.114(c) and 63.117(e), § 63.1335(f), alternative monitoring parameters, and § 63.1335(e)(8), submission of an operating permit, respectively, shall apply for the purposes of this subpart.

(6) When the Notification of Compliance Status requirements contained in § 63.152(b) are referred to in §§ 63.114, 63.117, and 63.118, the Notification of Compliance Status requirements contained in § 63.1335(e)(5) shall apply for the purposes of this subpart.

(7) When the Periodic Report requirements contained in § 63.152(c) are referred to in §§ 63.117 and 63.118, the Periodic Report requirements contained in § 63.1335(e)(6) shall apply for the purposes of this subpart.

(8) When the definition of excursion in § 63.152(c)(2)(ii)(A) is referred to in § 63.118(f)(2), the definition of excursion in § 63.1334(f) of this subpart shall apply for the purposes of this subpart.

(9) When § 63.114(e) or § 63.117(f) specifies that an owner or operator shall submit the information required in § 63.152(b) in order to establish the parameter monitoring range, the owner or operator of an affected source shall comply with the provisions of § 63.1335(e)(5) for purposes of reporting information related to establishment of the parameter monitoring level for purposes of this subpart. Further, the term “level” shall apply when the term “range” is used in §§ 63.114, 63.117, and 63.118.

(10) When reports of process changes are required under § 63.118(g), (h), (i), or (j), paragraphs (a)(10)(i) through (a)(10)(iv) of this section shall apply for the purposes of this subpart. In addition, for the purposes of this subpart, paragraph (a)(10)(v) of this section applies, and § 63.118(k) does not apply to owners or operators of affected sources.

(i) For the purposes of this subpart, whenever a process change, as defined in § 63.115(e), is made that causes a Group 2 continuous process vent to become a Group 1 continuous process vent, the owner or operator shall submit a report within 180 days after the process change is made or with the next Periodic Report, whichever is later. A description of the process change shall be submitted with the report of the process change, and the owner or operator of the affected source shall comply with the Group 1 provisions in §§ 63.113 through 63.118 in accordance with § 63.1310(i)(2)(ii) or (i)(2)(iii), as applicable.

(ii) Whenever a process change, as defined in § 63.115(e), is made that causes a Group 2 continuous process vent with a TRE greater than 4.0 to become a Group 2 continuous process vent with a TRE less than 4.0, the owner or operator shall submit a report within 180 days after the process change is made or with the next Periodic Report, whichever is later. A description of the process change shall be submitted with the report of the process change, and the owner or operator shall comply with the provisions in § 63.113(d) by the dates specified in § 63.1311.

(iii) Whenever a process change, as defined in § 63.115(e), is made that causes a Group 2 continuous process vent with a flow rate less than 0.005 standard cubic meter per minute to become a Group 2 continuous process vent with a flow rate of 0.005 standard cubic meter per minute or greater and a TRE index value less than or equal to 4.0, the owner or operator shall submit a report within 180 days after the process change is made or with the next Periodic Report, whichever is later. A description of the process change shall be submitted with the report of the process change, and the owner or operator shall comply with the provisions in § 63.113(d) by the dates specified in § 63.1311.

(iv) Whenever a process change, as defined in § 63.115(e), is made that causes a Group 2 continuous process vent with an organic HAP concentration less than 50 parts per million by volume to become a Group 2 continuous process vent with an organic HAP concentration of 50 parts per million by volume or greater and a TRE index value less than or equal to 4.0, the owner or operator shall submit a report within 180 days after the process change is made or with the next Periodic Report, whichever is later. A description of the process change shall be submitted with the report of the process change, and the owner or operator shall comply with the provisions in § 63.113(d) by the dates specified in § 63.1311.

(v) The owner or operator is not required to submit a report of a process change if one of the conditions listed in paragraphs (a)(10)(v)(A), (a)(10)(v)(B), (a)(10)(v)(C), or (a)(10)(v)(D) of this section is met.

(A) The process change does not meet the definition of a process change in § 63.115(e);

(B) The vent stream flow rate is recalculated according to § 63.115(e) and the recalculated value is less than 0.005 standard cubic meter per minute;

(C) The organic HAP concentration of the vent stream is recalculated according to § 63.115(e) and the recalculated value is less than 50 parts per million by volume; or

(D) The TRE index value is recalculated according to § 63.115(e) and the recalculated value is greater than 4.0, or for the affected sources producing methyl methacrylate butadiene styrene resin the recalculated value is greater than 6.7.

(11) When the provisions of § 63.116(c)(3) and (c)(4) specify that Method 18, 40 CFR part 60, appendix A shall be used, Method 18 or Method 25A, 40 CFR part 60, appendix A may be used for the purposes of this subpart. The use of Method 25A, 40 CFR part 60, appendix A shall conform with the requirements in paragraphs (a)(11)(i) and (a)(11)(ii) of this section.

(i) The organic HAP used as the calibration gas for Method 25A, 40 CFR part 60, appendix A shall be the single organic HAP representing the largest percent by volume of the emissions.

(ii) The use of Method 25A, 40 CFR part 60, appendix A is acceptable if the response from the high-level calibration gas is at least 20 times the standard deviation of the response from the zero calibration gas when the instrument is zeroed on the most sensitive scale.

(12) When § 63.118, periodic reporting and recordkeeping requirements, refers to § 63.152(f), the recordkeeping requirements in § 63.1335(d) shall apply for purposes of this subpart.

(13) If a batch process vent or aggregate batch vent stream is combined with a continuous process vent, the owner or operator of the affected source containing the combined vent stream shall comply with paragraph (a)(13)(i); with paragraph (a)(13)(ii) and with paragraph (a)(13)(iii) or (iv); or with paragraph (a)(13)(v) of this section, as appropriate.

(i) If a batch process vent or aggregate batch vent stream is combined with a Group 1 continuous process vent prior to the combined vent stream being routed to a control device, the owner or operator of the affected source containing the combined vent stream shall comply with the requirements in paragraph (a)(13)(i)(A) or (B) of this section.

(A) All requirements for a Group 1 process vent stream in §§ 63.113 through 63.118, except as otherwise provided in this section. As specified in § 63.1333(a)(1), performance tests shall be conducted at maximum representative operating conditions. For the purpose of conducting a performance test on a combined vent stream, maximum representative operating conditions shall be when batch emission episodes are occurring that result in the highest organic HAP emission rate (for the combined vent stream) that is achievable during one of the periods listed in § 63.1333(a)(1)(i) or § 63.1333(a)(1)(ii), without causing any of the situations described in paragraphs (a)(13)(i)(A)(1) through (3) to occur.

(1) Causing damage to equipment.

(2) Necessitating that the owner or operator make product that does not meet an existing specification for sale to a customer; or

(3) Necessitating that the owner or operator make product in excess of demand.

(B) Comply with the provisions in § 63.1313(b)(1), as allowed under § 63.1313(b).

(ii) If a batch process vent or aggregate batch vent stream is combined with a continuous process vent prior to the combined vent stream being routed to a recovery device, the TRE index value for the combined vent stream shall be calculated at the exit of the last recovery device. The TRE shall be calculated during periods when one or more batch emission episodes are occurring that result in the highest organic HAP emission rate (in the combined vent stream that is being routed to the recovery device) that is achievable during the 6-month period that begins 3 months before and ends 3 months after the TRE calculation, without causing any of the situations described in paragraphs (a)(13)(ii)(A) through (C) to occur.

(A) Causing damage to equipment.

(B) Necessitating that the owner or operator make product that does not meet an existing specification for sale to a customer; or

(C) Necessitating that the owner or operator make product in excess of demand.

(iii) If the combined vent stream described in paragraph (a)(10)(ii) of this section meets the requirements in paragraphs (a)(13)(iii)(A), (B), and (C) of this section, the combined vent stream shall be subject to the requirements for Group 1 process vents in §§ 63.113 through 63.118, except as otherwise provided in this section, as applicable. Performance tests for the combined vent stream shall be conducted at maximum operating conditions, as described in paragraph (a)(13)(i) of this section.

(A) The TRE index value of the combined stream is less than or equal to 1.0;

(B) The flow rate of the combined vent stream is greater than or equal to 0.005 standard cubic meter per minute; and

(C) The total organic HAP concentration is greater than or equal to 50 parts per million by volume for the combined vent stream.

(iv) If the combined vent stream described in paragraph (a)(10)(ii) of this section meets the requirements in paragraph (a)(13)(iv)(A), (B), or (C) of this section, the combined vent stream shall be subject to the requirements for Group 2 process vents in §§ 63.113 through 63.118, except as otherwise provided in this section, as applicable.

(A) The TRE index value of the combined vent stream is greater than 1.0;

(B) The flow rate of the combined vent stream is less than 0.005 standard cubic meter per minute; or

(C) The total organic HAP concentration is less than 50 parts per million by volume for the combined vent stream.

(v) If a batch process vent or aggregate batch vent stream is combined with a Group 2 continuous process vent, the owner or operator shall comply with the requirements in either paragraph (a)(13)(v)(A) or (a)(13)(v)(B) of this section.

(A) The owner or operator shall comply with the requirements in §§ 63.113 through 63.118 for Group 1 process vents; or

(B) The owner or operator shall comply with § 63.1322(e)(2) for batch process vents and aggregate batch vent streams.

(14) If any gas stream that originates outside of an affected source that is subject to this subpart is normally conducted through the same final recovery device as any continuous process vent stream subject to this subpart, the owner or operator of the affected source with the combined vent stream shall comply with all requirements in §§ 63.113 through 63.118 of subpart G of this part, except as otherwise noted in this section, as applicable.

(i) Instead of measuring the vent stream flow rate at the sampling site specified in § 63.115(b)(1), the sampling site for vent stream flow rate shall be prior to the final recovery device and prior to the point at which the gas stream that is not controlled under this subpart is introduced into the combined vent stream.

(ii) Instead of measuring total organic HAP or TOC concentrations at the sampling site specified in § 63.115(c)(1), the sampling site for total organic HAP or TOC concentration shall be prior to the final recovery device and prior to the point at which the gas stream that is not controlled under this subpart is introduced into the combined vent stream.

(iii) The efficiency of the final recovery device (determined according to paragraph (a)(14)(iv) of this section) shall be applied to the total organic HAP or TOC concentration measured at the sampling site described in paragraph (a)(14)(ii) of this section to determine the exit concentration. This exit concentration of total organic HAP or TOC shall then be used to perform the calculations outlined in § 63.115(d)(2)(iii) and § 63.115(d)(2)(iv), for the combined vent stream exiting the final recovery device.

(iv) The efficiency of the final recovery device is determined by measuring the total organic HAP or TOC concentration using Method 18 or 25A, 40 CFR part 60, appendix A, at the inlet to the final recovery device after the introduction of any gas stream that is not controlled under this subpart, and at the outlet of the final recovery device.

(15) When § 63.115(c)(3)(ii)(B) and (d)(2)(iv) and § 63.116(c)(3)(ii)(B) and (c)(4)(ii)(C) refer to Table 2 of subpart F of this part, the owner or operator is only required to consider organic HAP listed on Table 6 of this subpart for purposes of this subpart.

(16) The compliance date for continuous process vents subject to the provisions of this section is specified in § 63.1311.

(17) In § 63.116(a), instead of the reference to § 63.11(b), the requirements in § 63.1333(e) shall apply.

(18) When a combustion device is used to comply with the 20 parts per million by volume outlet concentration standard specified in § 63.113(a)(2), the correction to 3 percent oxygen is only required when supplemental combustion air is used to combust the emissions, for the purposes of this subpart. In addition, the correction to 3 percent oxygen specified in § 63.116(c)(3) and (c)(3)(iii) is only required when supplemental combustion air is used to combust the emissions, for the purposes of this subpart. Finally, when a combustion device is used to comply with the 20 parts per million by volume outlet concentration standard specified in § 63.113(a)(2), an owner or operator shall record and report the outlet concentration required in § 63.117(a)(4)(ii) and (a)(4)(iv) corrected to 3 percent oxygen when supplemental combustion air is used to combust the emissions, for the purposes of this subpart. When supplemental combustion air is not used to combust the emissions, an owner or operator may record and report the outlet concentration required in § 63.117(a)(4)(ii) and (a)(4)(iv) on an uncorrected basis or corrected to 3 percent oxygen, for the purposes of this subpart.

(19) During periods of startup or shutdown, as an alternative to using the procedures specified in § 63.116, an owner or operator of an affected source or emission unit subject to an emission limit expressed as mass emissions per mass product may demonstrate compliance with the limit in accordance with paragraph (a)(19)(i), (ii), or (iii) of this section.

(i) Keep records establishing that the raw material introduced and product discharged rates were both zero.

(ii) Divide the organic HAP emission rate during startup or shutdown by the rate of polymer produced from the most recent performance test associated with a production rate greater than zero according to § 63.1318(b)(1). Keep records of this calculation.

(iii) Keep records establishing that the operating parameters of the control device used to comply with the emission limit in § 63.113(a)(1) or (2) were maintained at the level established to meet the emission limit at maximum representative operating conditions.

§ 63.1319 PET and polystyrene affected sources—recordkeeping provisions.

(a) Except as specified in paragraphs (b) and (c) of this section, owners or operators using a control or recovery device to comply with § 63.1316 shall comply with the applicable recordkeeping provisions specified in § 63.1315(a), except that, for the purposes of this paragraph (a), references to group determinations (i.e., total resource effectiveness) do not apply, and owners or operators are not required to comply with § 63.113.

(b) Records demonstrating compliance with the applicability determination procedure for PET affected sources using a dimethyl terephthalate process. Owners or operators complying with § 63.1316(b)(1)(i) by demonstrating that mass emissions per mass product are less than or equal to the level specified in § 63.1316(b)(1)(i) (i.e., 0.12 kg organic HAP per Mg of product) shall keep the following records.

(1) Results of the mass emissions per mass product calculation specified in § 63.1318(b).

(2) Records of any change in process operation that increases the mass emissions per mass product.

§ 63.1320 PET and polystyrene affected sources—reporting provisions.

(a) Except as specified in paragraph (b) of this section, owners and operators using a control or recovery device to comply with § 63.1316 shall comply with the applicable reporting provisions specified in § 63.1315(a), except that, for the purposes of this paragraph (a), references to group determinations (i.e., total resource effectiveness) do not apply, and owners or operators are not required to comply with § 63.113.

(b) Reporting for PET Affected Sources Using a Dimethyl Terephthalate Process. Owners or operators complying with § 63.1316 by demonstrating that mass emissions per mass product are less than or equal to the level specified in § 63.1316(b)(1)(i) (i.e., 0.12 kg organic HAP per Mg of product) shall comply with paragraphs (b)(1) through (b)(3) of this section.

(1) Include the information specified in § 63.1319(b)(2) in each Periodic Report, required by § 63.1335(e)(6), as appropriate.

(2) Include the information specified in § 63.1319(b)(1) in the Notification of Compliance Status, required by § 63.1335(e)(5).

(3) Whenever a process change, as defined in § 63.115(e), is made that causes emissions from continuous process vents in the collection of material recovery sections (i.e., methanol recovery) within the affected source to be greater than 0.12 kg organic HAP per Mg of product, the owner or operator shall submit a report within 180 days after the process change is made or the information regarding the process change is known to the owner or operator. This report may be included in the next Periodic Report. The report shall include the information specified in § 63.1319(b)(1) and a description of the process change.

§ 63.1326 Batch process vents—recordkeeping provisions.

(a) Group determination records for batch process vents. Except as provided in paragraphs (a)(7) and (a)(8) of this section, each owner or operator of an affected source shall maintain the records specified in paragraphs (a)(1) through (a)(6) of this section for each batch process vent subject to the group determination procedures of § 63.1323. Except for paragraph (a)(1) of this section, the records required by this paragraph (a) are restricted to the information developed and used to make the group determination under §§ 63.1323(b) through 63.1323(g), as appropriate. If an owner or operator did not need to develop certain information (e.g., annual average batch vent flow rate) to determine the group status, this paragraph (a) does not require that additional information be developed. Paragraph (a)(9) of this section specifies the recordkeeping requirements for Group 2 batch process vents that are exempt from the batch mass input limitation provisions, as allowed under § 63.1322(h).

(1) An identification of each unique product that has emissions from one or more batch emission episodes venting from the batch process vent, along with an identification of the single highest-HAP recipe for each product and the mass of HAP fed to the reactor for that recipe.

(2) A description of, and an emission estimate for, each batch emission episode, and the total emissions associated with one batch cycle, as described in either paragraph (a)(2)(i) or (a)(2)(ii) of this section, as appropriate.

(i) If the group determination is based on the expected mix of products, records shall include the emission estimates for the single highest-HAP recipe of each unique product identified in paragraph (a)(1) of this section that was considered in making the group determination under § 63.1323.

(ii) If the group determination is based on the single highest-HAP recipe (considering all products produced or processed in the batch unit operation), records shall include the emission estimates for the single highest-HAP recipe.

(3) Total annual uncontrolled TOC or organic HAP emissions, determined at the exit from the batch unit operation before any control device, determined in accordance with § 63.1323(b).

(i) For Group 2 batch process vents, said emissions shall be determined at the batch mass input limitation.

(ii) For Group 1 batch process vents, said emissions shall be those used to determine the group status of the batch process vent.

(4) The annual average batch vent flow rate for the batch process vent, determined in accordance with § 63.1323(e).

(5) The cutoff flow rate, determined in accordance with § 63.1323(f).

(6) The results of the batch process vent group determination, conducted in accordance with § 63.1323(g).

(7) If a batch process vent is subject to § 63.1322(a) or (b), none of the records in paragraphs (a)(1) through (a)(6) of this section are required.

(8) If the total annual emissions from the batch process vent during the group determination are less than the appropriate level specified in § 63.1323(d), only the records in paragraphs (a)(1) through (a)(3) of this section are required.

(9) For each Group 2 batch process vent that is exempt from the batch mass input limitation provisions because it meets the criteria of § 63.1322(h), the records specified in paragraphs (a)(9)(i) and (ii) shall be maintained.

(i) Documentation of the maximum design capacity of the TPPU; and

(ii) The mass of HAP or material that can be charged annually to the batch unit operation at the maximum design capacity.

(b) Compliance demonstration records. Each owner or operator of a batch process vent or aggregate batch vent stream complying with § 63.1322(a) or (b), shall keep the following records, as applicable, readily accessible:

(1) The annual mass emissions of halogen atoms in the batch process vent or aggregate batch vent stream determined according to the procedures specified in § 63.1323(h);

(2) If the owner or operator of a batch process vent has chosen to comply with § 63.1322(a)(2), records documenting the batch cycle percent reduction as specified in § 63.1325(c)(2); and

(3) When using a flare to comply with § 63.1322 (a)(1), (a)(3), (b)(1), or (b)(3):

(i) The flare design (i.e., steam-assisted, air-assisted or non-assisted);

(ii) All visible emission readings, heat content determinations, flow rate measurements, and exit velocity determinations made during the compliance determination required by § 63.1333(e); and

(iii) Periods when all pilot flames were absent.

(4) The following information when using a control device to meet the percent reduction requirement specified in § 63.1322(a)(2), (a)(3), (b)(2), or (b)(3):

(i) For an incinerator or non-combustion control device, the percent reduction of organic HAP or TOC achieved, as determined using the procedures specified in § 63.1325(c) for batch process vents and § 63.1325(e) for aggregate batch vent streams;

(ii) For a boiler or process heater, a description of the location at which the vent stream is introduced into the boiler or process heater;

(iii) For a boiler or process heater with a design heat input capacity of less than 44 megawatts and where the vent stream is introduced with combustion air or used as a secondary fuel and is not mixed with the primary fuel, the percent reduction of organic HAP or TOC achieved, as determined using the procedures specified in § 63.1325(c) for batch process vents and § 63.1325(e) for aggregate batch vent streams; and

(iv) For a scrubber or other halogen reduction device following a combustion device to control halogenated batch process vents or halogenated aggregate batch vent streams, the percent reduction of total hydrogen halides and halogens as determined under § 63.1325(d)(3) or the emission limit determined under § 63.1325(d)(4).

(5) When complying with the 20 parts per million by volume outlet concentration standard specified in § 63.1322(b)(2), records of the outlet concentration of organic HAP or TOC on a dry basis. If supplemental combustion air is used to combust the emissions, the outlet concentration shall be corrected to 3 percent oxygen. If supplemental combustion air is not used, a correction to 3 percent oxygen is not required.

(c) Establishment of parameter monitoring level records. For each parameter monitored according to § 63.1324(c) and Table 7 of this subpart, or for alternate parameters and/or parameters for alternate control devices monitored according to § 63.1327(f) as allowed under § 63.1324(d), maintain documentation showing the establishment of the level that indicates proper operation of the control device as required by § 63.1324(f) for parameters specified in § 63.1324(c) and as required by § 63.1335(e) for alternate parameters. Said documentation shall include the parameter monitoring data used to establish the level.

(d) Group 2 batch process vent continuous compliance records. The owner or operator of a Group 2 batch process vent shall comply with either paragraph (d)(1) or (d)(2) of this section, as appropriate.

(1) The owner or operator of a Group 2 batch process vent that has chosen to comply with § 63.1322(g) shall keep the following records readily accessible:

(i) Records designating the established batch mass input limitation required by § 63.1322(g)(1) and specified in § 63.1325(g).

(ii) Records specifying the mass of HAP or material charged to the batch unit operation.

(2) The owner or operator of a Group 2 batch process vent that has chosen to comply with § 63.1322(f) shall keep the following records readily accessible:

(i) Records designating the established batch mass input limitation required by § 63.1322(f)(1) and specified in § 63.1325(g).

(ii) Records specifying the mass of HAP or material charged to the batch unit operation.

(e) Controlled batch process vent continuous compliance records. Each owner or operator of a batch process vent that has chosen to use a control device to comply with § 63.1322(a) shall keep the following records, as applicable, readily accessible:

(1) Continuous records of the equipment operating parameters specified to be monitored under § 63.1324(c) as applicable, and listed in Table 7 of this subpart, or specified by the Administrator in accordance with § 63.1327(f) as allowed under § 63.1324(d). Said records shall be kept as specified under § 63.1335(d), except as specified in paragraphs (e)(1)(i) and (e)(1)(ii) of this section.

(i) For flares, the records specified in Table 7 of this subpart shall be maintained in place of continuous records.

(ii) For carbon adsorbers, the records specified in Table 7 of this subpart shall be maintained in place of batch cycle daily averages.

(2) Records of the batch cycle daily average value of each continuously monitored parameter, except as provided in paragraph (e)(2)(iii) of this section, as calculated using the procedures specified in paragraphs (e)(2)(i) and (e)(2)(ii) of this section.

(i) The batch cycle daily average shall be calculated as the average of all parameter values measured for an operating day during those batch emission episodes, or portions thereof, in the batch cycle that the owner or operator has selected to control.

(ii) Monitoring data recorded during periods of monitoring system breakdowns, repairs, calibration checks, and zero (low-level) and high-level adjustments shall not be included in computing the batch cycle daily averages. In addition, monitoring data recorded during periods of non-operation of the TPPU (or specific portion thereof) resulting in cessation of organic HAP emissions, or periods of start-up, shutdown, or malfunction shall not be included in computing the batch cycle daily averages.

(iii) If all recorded values for a monitored parameter during an operating day are above the minimum or below the maximum level established in accordance with § 63.1324(f), the owner or operator may record that all values were above the minimum or below the maximum level established rather than calculating and recording a batch cycle daily average for that operating day.

(3) Hourly records of whether the flow indicator for bypass lines specified in § 63.1324(e)(1) was operating and whether a diversion was detected at any time during the hour. Also, records of the times of all periods when the vent is diverted from the control device or the flow indicator specified in § 63.1324(e)(1) is not operating.

(4) Where a seal or closure mechanism is used to comply with § 63.1324(e)(2), hourly records of whether a diversion was detected at any time are not required. The owner or operator shall record whether the monthly visual inspection of the seals or closure mechanisms has been done, and shall record the occurrence of all periods when the seal mechanism is broken, the bypass line damper or valve position has changed, or the key for a lock-and-key type configuration has been checked out, and records of any car-seal that has broken.

(5) Records specifying the times and duration of periods of monitoring system breakdowns, repairs, calibration checks, and zero (low-level) and high-level adjustments. In addition, records specifying any other periods of process or control device operation when monitors are not operating.

(f) Aggregate batch vent stream continuous compliance records. In addition to the records specified in paragraphs (b) and (c) of this section, each owner or operator of an aggregate batch vent stream using a control device to comply with § 63.1322(b)(1) or (b)(2) shall keep the following records readily accessible:

(1) Continuous records of the equipment operating parameters specified to be monitored under § 63.1324(c) and listed in Table 7 of this subpart, as applicable, or specified by the Administrator in accordance with § 63.1327(f), as allowed under § 63.1324(d), with the exceptions listed in (f)(1)(i) and (f)(1)(ii) of this section.

(i) For flares, the records specified in Table 7 of this subpart shall be maintained in place of continuous records.

(ii) For carbon adsorbers, the records specified in Table 7 of this subpart shall be maintained in place of daily averages.

(2) Records of the daily average value of each continuously monitored parameter for each operating day determined according to the procedures specified in § 63.1335(d).

(3) For demonstrating compliance with the monitoring of bypass lines as specified in § 63.1324(e), records as specified in paragraphs (e)(3) or (e)(4) of this section, as appropriate.

(g) Documentation supporting the establishment of the batch mass input limitation shall include the information specified in paragraphs (g)(1) through (g)(5) of this section, as appropriate.

(1) Identification of whether the purpose of the batch mass input limitation is to comply with § 63.1322(f)(1) or (g)(1).

(2) Identification of whether the batch mass input limitation is based on the single highest-HAP recipe (considering all products) or on the expected mix of products for the batch process vent as allowed under § 63.1323(a)(1).

(3) Definition of the operating year, for the purposes of determining compliance with the batch mass input limitation.

(4) If the batch mass input limitation is based on the expected mix of products, the owner or operator shall provide documentation that describes as many scenarios for differing mixes of products (i.e., how many of each type of product) as the owner or operator desires the flexibility to accomplish. Alternatively, the owner or operator shall provide a description of the relationship among the mix of products that will allow a determination of compliance with the batch mass input limitation under any number of scenarios.

(5) The mass of HAP or material allowed to be charged to the batch unit operation per year under the batch mass input limitation.

§ 63.1327 Batch process vents—reporting requirements.

(a) The owner or operator of a batch process vent or aggregate batch vent stream at an affected source shall submit the information specified in paragraphs (a)(1) through (a)(6) of this section, as appropriate, as part of the Notification of Compliance Status specified in § 63.1335(e)(5).

(1) For each batch process vent complying § 63.1322(a) and each aggregate batch vent stream complying § 63.1322(b), the information specified in § 63.1326 (b) and (c), as applicable.

(2) For each Group 2 batch process vent with annual emissions less than the level specified in § 63.1323(d), the information specified in § 63.1326(d)(1)(i).

(3) For each Group 2 batch process vent with annual emissions greater than or equal to the level specified in § 63.1323(d), the information specified in § 63.1326(d)(2)(i).

(4) For each batch process vent subject to the group determination procedures, the information specified in § 63.1326(a), as appropriate.

(5) For each Group 2 batch process vent that is exempt from the batch mass input limitation provisions because it meets the criteria of § 63.1322(h), the information specified in § 63.1326(a)(1) through (3), and the information specified in § 63.1326(a)(4) through (6) as applicable, calculated at the conditions specified in § 63.1322(h).

(6) When engineering assessment has been used to estimate emissions from a batch emissions episode and the criteria specified in § 63.1323(b)(6)(i)(A) or (B) have been met, the owner or operator shall submit the information demonstrating that the criteria specified in § 63.1323(b)(6)(i)(A) or (B) have been met as part of the Notification of Compliance Status required by § 63.1335(e)(5).

(b) Whenever a process change, as defined in § 63.1323(i)(1), is made that causes a Group 2 batch process vent to become a Group 1 batch process vent, the owner or operator shall notify the Administrator and submit a description of the process change within 180 days after the process change is made or with the next Periodic Report, whichever is later. The owner or operator of an affected source shall comply with the Group 1 batch process vent provisions in §§ 63.1321 through 63.1327 in accordance with § 63.1310(i)(2)(ii).

(c) Whenever a process change, as defined in § 63.1323(i)(1), is made that causes a Group 2 batch process vent with annual emissions less than the level specified in § 63.1323(d) for which the owner or operator has chosen to comply with § 63.1322(g) to have annual emissions greater than or equal to the level specified in § 63.1323(d) but remains a Group 2 batch process vent, or if a process change is made that requires the owner or operator to redetermine the batch mass input limitation as specified in § 63.1323(i)(3), the owner or operator shall submit a report within 180 days after the process change is made or with the next Periodic Report, whichever is later. The following information shall be submitted:

(1) A description of the process change;

(2) The batch mass input limitation determined in accordance with § 63.1322(f)(1).

(d) Whenever a process change, as defined in § 63.1323(j)(1), is made that could potentially cause the percent reduction for all process vents at a new SAN affected source using a batch process to be less than 84 percent, the owner or operator shall notify the Administrator and submit a description of the process change within 180 days after the process change is made or with the next Periodic Report, whichever is later. The owner or operator shall comply with § 63.1322(a)(3) and all associated provisions in accordance with § 63.1310(i).

(e) The owner or operator is not required to submit a report of a process change if one of the conditions specified in paragraphs (e)(1) or (e)(2) of this section is met.

(1) The change does not meet the description of a process change in § 63.1323(i) or (j).

(2) The redetermined group status remains Group 2 for an individual batch process vent with annual emissions greater than or equal to the level specified in § 63.1323(d) and the batch mass input limitation does not decrease, a Group 2 batch process vent with annual emissions less than the level specified in § 63.1323(d) complying with § 63.1322(g) continues to have emissions less than the level specified in § 63.1323(d) and the batch mass input limitation does not decrease, or the achieved emission reduction remains at 84 percent or greater for new SAN affected sources using a batch process.

(f) If an owner or operator uses a control device other than those specified in § 63.1324(c) and listed in Table 7 of this subpart or requests approval to monitor a parameter other than those specified § 63.1324(c) and listed in Table 7 of this subpart, the owner or operator shall submit a description of planned reporting and recordkeeping procedures, as specified in § 63.1335(f), as part of the Precompliance Report required under § 63.1335(e)(3). The Administrator will specify appropriate reporting and recordkeeping requirements as part of the review of the Precompliance Report.

(g) Owners or operators of affected sources complying with § 63.1324(e), shall comply with paragraph (g)(1) or (g)(2) of this section, as appropriate.

(1) Submit reports of the times of all periods recorded under § 63.1326(e)(3) when the batch process vent is diverted from the control device through a bypass line, with the next Periodic Report.

(2) Submit reports of all occurrences recorded under § 63.1326(e)(4) in which the seal mechanism is broken, the bypass line damper or valve position has changed, or the key to unlock the bypass line damper or valve was checked out, with the next Periodic Report.

§ 63.1329 Process contact cooling towers provisions.

(c) Existing affected source requirements. The owner or operator of an existing affected source subject to this section who manufactures PET using a continuous terephthalic acid high viscosity multiple end finisher process and who is subject or becomes subject to 40 CFR part 60, subpart DDD, shall maintain an ethylene glycol concentration in the process contact cooling tower at or below 6.0 percent by weight averaged on a daily basis over a rolling 14-day period of operating days. Compliance with this paragraph (c) shall be determined as specified in paragraphs (c)(1) through (c)(4) of this section. It should be noted that compliance with this paragraph (c) does not exempt owners or operators from complying with the provisions of § 63.1330 for those process wastewater streams that are sent to the process contact cooling tower.

(1) To determine the ethylene glycol concentration, owners or operators shall follow the procedures specified in 40 CFR 60.564(j)(1), except as provided in paragraph (c)(2) of this section.

(i) At least one sample per operating day shall be collected using the procedures specified in 40 CFR 60.564(j)(1)(i). An average ethylene glycol concentration by weight shall be calculated on a daily basis over a rolling 14-day period of operating days. Each daily average ethylene glycol concentration so calculated constitutes a performance test.

(ii) The owner or operator may elect to reduce the sampling program to any 14 consecutive operating day period once every two calendar months, if at least seventeen consecutive 14-day rolling average concentrations immediately preceding the reduced sampling program are each less than 1.2 weight percent ethylene glycol. If the average concentration obtained over the 14 operating day sampling during the reduced test period exceeds the upper 95 percent confidence interval calculated from the most recent test results in which no one 14-day average exceeded 1.2 weight percent ethylene glycol, then the owner or operator shall reinstitute a daily sampling program. The 95 percent confidence interval shall be calculated as specified in paragraph (c)(1)(iii) of this section. A reduced program may be reinstituted if the requirements specified in this paragraph (c)(1)(ii) are met.

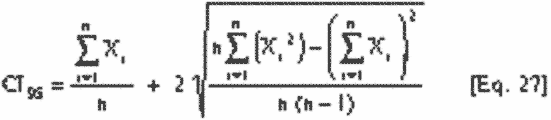

(iii) The upper 95 percent confidence interval shall be calculated using the Equation 27 of this subpart:

Where:

CI95 = 95 percent confidence interval

Xi = daily ethylene glycol concentration for each operating day used to calculate each 14-day rolling average used in test results to justify implementing the reduced testing program.

n = number of ethylene glycol concentrations.

(2) Measuring an alternative parameter, such as carbon oxygen demand or biological oxygen demand, that is demonstrated to be directly proportional to the ethylene glycol concentration shall be allowed. Such parameter shall be measured during the initial 14-day performance test during which the facility is shown to be in compliance with the ethylene glycol concentration standard whereby the ethylene glycol concentration is determined using the procedures described in paragraph (c)(1) of this section. The alternative parameter shall be measured on a daily basis and the average value of the alternative parameter shall be calculated on a daily basis over a rolling 14-day period of operating days. Each daily average value of the alternative parameter constitutes a performance test.

(i) Where 40 CFR 60.564(j)(1) requires the use of ASTM D2908-74 or 91, “Standard Practice for Measuring Volatile Organic Matter in Water by Aqueous-Injection Gas Chromatography,” ASTM D2908-91 (2011), D2908-91 (2005), D2908-91 (2001), D2908-91, or D2908-74 (all standards incorporated by reference, see § 63.14) may be used.

(ii) Where 40 CFR 60.564(j)(1)(i) requires the use of ASTM D3370-76 or 95a, “Standard Practices for Sampling Water from Closed Conduits,” ASTM D3370-10, D3370-08, D3370-07, D3370-95a, or D3370-76 (all standards incorporated by reference, see § 63.14) may be used.

(3) During each performance test, daily measurement and daily average 14-day rolling averages of the ethylene glycol concentration in the cooling tower water shall be recorded. For the initial performance test, these records shall be submitted in the Notification of Compliance Status report.

(4) All periods when the 14-day rolling average exceeds the standard shall be reported in the Periodic Report.

§ 63.1331 Equipment leak provisions.

(a) Except § 63.165 and as provided for in paragraphs (b) and (c) of this section, the owner or operator of each affected source shall comply with the requirements of subpart H of this part, with the differences noted in paragraphs (a)(1) through (13) of this section.

(4) As specified in § 63.1335(e)(5), the Notification of Compliance Status required by paragraphs § 63.182(a)(2) and § 63.182(c) shall be submitted within 150 days (rather than 90 days) of the applicable compliance date specified in § 63.1311 for the equipment leak provisions.

(5) The information specified by § 63.182(a)(3) and § 63.182(d) (i.e., Periodic Reports) shall be submitted as part of the Periodic Reports required by § 63.1335(e)(6).

(c) (4) When a leak is detected, the following information shall be recorded and kept for 2 years and reported in the next periodic report:

(i) The instrument and the equipment identification number and the operator name, initials or identification number.

(ii) The date the leak was detected and the date of first attempt to repair the leak.

(iii) The date of successful repair of the leak.

§ 63.1333 Additional requirements for performance testing.

(a) Performance tests shall be conducted under such conditions as the Administrator specifies to the owner or operator based on representative performance of the affected source for the period being tested and in accordance with § 63.7(a)(1), (a)(3), (d), (e)(2), (e)(4), (g), and (h), with the exceptions specified in paragraphs (a)(1) through (5) of this section and the additions specified in paragraphs (b) through (d) of this section. Representative conditions exclude periods of startup and shutdown unless specified by the Administrator or an applicable subpart. The owner or operator may not conduct performance tests during periods of malfunction. The owner or operator must record the process information that is necessary to document operating conditions during the test and include in such record an explanation to support that such conditions represent normal operation. Upon request, the owner or operator shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests. Sections 63.1314 through 63.1330 also contain specific testing requirements.

(4) The owner or operator shall notify the Administrator of the intention to conduct a performance test at least 30 days before the performance test is scheduled to allow the Administrator the opportunity to have an observer present during the test. If after 30 days notice for an initially scheduled performance test, there is a delay (due to operational problems, etc.) in conducting the scheduled performance test, the owner or operator of an affected facility shall notify the Administrator as soon as possible of any delay in the original test date, either by providing at least 7 days prior notice of the rescheduled date of the performance test, or by arranging a rescheduled date with the Administrator by mutual agreement.

§ 63.1335 General recordkeeping and reporting provisions.

(a) Data retention. Unless otherwise specified in this subpart, the owner or operator of an affected source shall keep copies of all applicable records and reports required by this subpart for at least 5 years, as specified in paragraph (a)(1) of this section, with the exception listed in paragraph (a)(2) of this section.

(1) All applicable records shall be maintained in such a manner that they can be readily accessed. The most recent 6 months of records shall be retained on site or shall be accessible from a central location by computer or other means that provides access within 2 hours after a request. The remaining 4 and one-half years of records may be retained offsite. Records may be maintained in hard copy or computer-readable form including, but not limited to, on paper, microfilm, computer, floppy disk, magnetic tape, or microfiche.

(2) If an owner or operator submits copies of reports to the appropriate EPA Regional Office, the owner or operator is not required to maintain copies of reports. If the EPA Regional Office has waived the requirement of § 63.10(a)(4)(ii) for submittal of copies of reports, the owner or operator is not required to maintain copies of those reports.

(b) Requirements of subpart A of this part. The owner or operator of an affected source shall comply with the applicable recordkeeping and reporting requirements in subpart A of this part as specified in Table 1 of this subpart. These requirements include, but are not limited to, the requirements specified in paragraphs (b)(1) and (b)(2) of this section.

(1) Malfunction recordkeeping and reporting.

(i) Records of malfunctions. The owner or operator shall keep the records specified in paragraphs (b)(1)(i)(A) through (C) of this section.

(A) In the event that an affected unit fails to meet an applicable standard, record the number of failures. For each failure record the date, time, and duration of each failure.

(B) For each failure to meet an applicable standard, record and retain a list of the affected sources or equipment, an estimate of the quantity of each regulated pollutant emitted over any emission limit, and a description of the method used to estimate the emissions.

(C) Record actions taken to minimize emissions in accordance with § 63.1310(j)(4), and any corrective actions taken to return the affected unit to its normal or usual manner of operation.

(ii) Reports of malfunctions. If a source fails to meet an applicable standard, report such events in the Periodic Report. Report the number of failures to meet an applicable standard. For each instance, report the date, time, and duration of each failure. For each failure the report must include a list of the affected sources or equipment, an estimate of the quantity of each regulated pollutant emitted over any emission limit, and a description of the method used to estimate the emissions.

(d) Recordkeeping and documentation. Owners or operators required to keep continuous records shall keep records as specified in paragraphs (d)(1) through (10) of this section, unless an alternative recordkeeping system has been requested and approved as specified in paragraph (g) of this section, and except as provided in paragraph (h) of this section. If a monitoring plan for storage vessels pursuant to § 63.1314(a)(9) requires continuous records, the monitoring plan shall specify which provisions, if any, of paragraphs (d)(1) through (10) of this section apply. As described in § 63.1314(a)(9), certain storage vessels are not required to keep continuous records as specified in this paragraph. Owners and operators of such storage vessels shall keep records as specified in the monitoring plan required by § 63.1314(a)(9). Paragraphs (d)(8) and (d)(9) of this section specify documentation requirements.

(1) The monitoring system shall measure data values at least once every 15 minutes.

(2) The owner or operator shall record either each measured data value or block average values for 1 hour or shorter periods calculated from all measured data values during each period. If values are measured more frequently than once per minute, a single value for each minute may be used to calculate the hourly (or shorter period) block average instead of all measured values. Owners or operators of batch process vents shall record each measured data value.

(3) Daily average (or batch cycle daily average) values of each continuously monitored parameter shall be calculated for each operating day as specified in paragraphs (d)(3)(i) through (d)(3)(ii) of this section, except as specified in paragraphs (d)(6) and (d)(7) of this section.

(i) The daily average value or batch cycle daily average shall be calculated as the average of all parameter values recorded during the operating day, except as specified in paragraph (d)(7) of this section. For batch process vents, as specified in § 63.1326(e)(2)(i), only parameter values measured during those batch emission episodes, or portions thereof, in the batch cycle that the owner or operator has chosen to control shall be used to calculate the average. The calculated average shall cover a 24-hour period if operation is continuous, or the number of hours of operation per operating day if operation is not continuous.

(ii) The operating day shall be the period the owner or operator specifies in the operating permit or the Notification of Compliance Status for purposes of determining daily average values or batch cycle daily average values of monitored parameters.

(6) Records required when all recorded values are within the established limits. If all recorded values for a monitored parameter during an operating day are above the minimum level or below the maximum level established in the Notification of Compliance Status or operating permit, the owner or operator may record that all values were above the minimum level or below the maximum level rather than calculating and recording a daily average (or batch cycle daily average) for that operating day.

(7) Monitoring data recorded during periods identified in paragraphs (d)(7)(i) and (ii) of this section shall not be included in any average computed under this subpart. Records shall be kept of the times and durations of all such periods and any other periods during process or control device or recovery device operation when monitors are not operating.

(i) Monitoring system breakdowns, repairs, calibration checks, and zero (low-level) and high-level adjustments; or

(ii) Periods of non-operation of the affected source (or portion thereof), resulting in cessation of the emissions to which the monitoring applies.

(8) For continuous monitoring systems used to comply with this subpart, records documenting the completion of calibration checks, and records documenting the maintenance of continuous monitoring systems that are specified in the manufacturer's instructions or that are specified in other written procedures that provide adequate assurance that the equipment would reasonably be expected to monitor accurately.

(9) The owner or operator of an affected source granted a waiver under § 63.10(f) shall maintain the information, if any, specified by the Administrator as a condition of the waiver of recordkeeping or reporting requirements.

(10) For pressure relief devices in organic HAP service, keep records of the information specified in paragraphs (d)(10)(i) through (v) of this section, as applicable.

(i) A list of identification numbers for pressure relief devices that the owner or operator elects to equip with a closed-vent system and control device, subject to the provisions in § 63.1331(a)(9)(iv).

(ii) A list of identification numbers for pressure relief devices subject to the provisions in § 63.1331(a)(9)(i).

(iii) A list of identification numbers for pressure relief devices equipped with rupture disks, subject to the provisions in § 63.1331(a)(9)(ii)(B).

(iv) The dates and results of the Method 21 of 40 CFR part 60, appendix A, monitoring following a pressure release for each pressure relief device subject to the provisions in § 63.1331(a)(9)(i) and (ii). The results shall include:

(A) The background level measured during each compliance test.

(B) The maximum instrument reading measured at each piece of equipment during each compliance test.

(v) For pressure relief devices in organic HAP service subject to § 63.1331(a)(9)(iii), keep records of each pressure release to the atmosphere, including the following information:

(A) The source, nature, and cause of the pressure release.

(B) The date, time, and duration of the pressure release.

(C) The quantity of total HAP emitted during the pressure release and the calculations used for determining this quantity.

(D) The actions taken to prevent this pressure release.

(E) The measures adopted to prevent future such pressure releases.

(e) Reporting and notification. In addition to the reports and notifications required by subpart A of this part as specified in Table 1 of this subpart, the owner or operator of an affected source shall prepare and submit the reports listed in paragraphs (e)(3) through (9) of this section, as applicable. All reports required by this subpart, and the schedule for their submittal, are listed in Table 9 of this subpart.

(3) Precompliance Report. Owners or operators of affected sources requesting an extension for compliance; requesting approval to use alternative monitoring parameters, alternative continuous monitoring and recordkeeping or alternative controls; requesting approval to use engineering assessment to estimate emissions from a batch emissions episode, as described in § 63.1323(b)(6)(i)(C); or wishing to establish parameter monitoring levels according to the procedures contained in § 63.1334(c) or (d), shall submit a Precompliance Report according to the schedule described in paragraph (e)(3)(i) of this section. The Precompliance Report shall contain the information specified in paragraphs (e)(3)(ii) through (e)(3)(viii) of this section, as appropriate.

(i) Submittal dates. The Precompliance Report shall be submitted to the Administrator no later than December 19, 2000. If a Precompliance Report was submitted prior to June 19, 2000 and no changes need to be made to that Precompliance Report, the owner or operator shall re-submit the earlier report or submit notification that the previously submitted report is still valid. Unless the Administrator objects to a request submitted in the Precompliance Report within 45 days after its receipt, the request shall be deemed approved. For new affected sources, the Precompliance Report shall be submitted to the Administrator with the application for approval of construction or reconstruction required in paragraph (b)(2) of this section. Supplements to the Precompliance Report may be submitted as specified in paragraph (e)(3)(ix) of this section. To submit a Precompliance Report for the first time after the compliance date to request an extension for compliance; request approval to use alternative monitoring parameters, alternative continuous monitoring and recordkeeping or alternative controls; request approval to use engineering assessment to estimate emissions from a batch emissions episode, as described in § 63.1323(b)(6)(i)(C); or to request to establish parameter monitoring levels according to the procedures contained in § 63.1334(c) or (d), the owner or operator shall notify the Administrator at least 90 days before the planned change is to be implemented; the change shall be considered approved if the Administrator either approves the change in writing, or fails to disapprove the change in writing within 45 days of receipt.

(ii) A request for an extension for compliance, as specified in § 63.1311(e), may be submitted in the Precompliance Report. The request for a compliance extension shall include the data outlined in § 63.6(i)(6)(i)(A), (B), and (D), as required in § 63.1311(e)(1).

(iii) The alternative monitoring parameter information required in paragraph (f) of this section shall be submitted in the Precompliance Report if, for any emission point, the owner or operator of an affected source seeks to comply through the use of a control technique other than those for which monitoring parameters are specified in this subpart or in subpart G of this part or seeks to comply by monitoring a different parameter than those specified in this subpart or in subpart G of this part.

(iv) If the affected source seeks to comply using alternative continuous monitoring and recordkeeping as specified in paragraph (g) of this section, the owner or operator shall submit a request for approval in the Precompliance Report.

(v) The owner or operator shall report the intent to use alternative emission standards to comply with the provisions of this subpart in the Precompliance Report. The Administrator may deem alternative emission standards to be equivalent to the standard required by the subpart, under the procedures outlined in § 63.6(g).