FGIS-952-1 Sanitation Inspection Report (Beans, Peas, and Lentils)

Reporting and Recordkeeping Requirements (US Grain Standards Act and Agricultural Marketing Act of 1946)

fgis-952-1.xls

Reporting and Recordkeeping Requirements - State, Local, Tribal

OMB: 0581-0309

⚠️ Notice: This form may be outdated. More recent filings and information on OMB 0581-0309 can be found here:

Document [xlsx]

Download: xlsx | pdf

EXHIBIT

INSTRUCTIONS

CONTACT

Overview

FORMEXHIBIT

INSTRUCTIONS

CONTACT

Sheet 1: FORM

| FORM APPROVED OMB NO. 0580-0013: According to the Paperwork Reduction Act of 1995, an agency may not conduct or sponsor, and a person is not required to respond to a collection of information unless it displays a valid OMB control number. The valid OMB control number for this information collection is 00580-0013. The time required to complete this information collection is estimated to average 1 hour per response and 1 minute of recordkeeping, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information. | |||||||||||||||||

| SANITATION INSPECTION REPORT | |||||||||||||||||

| (BEANS, PEAS, AND LENTILS) | |||||||||||||||||

| SANITATION INSPECTION OF (Name and Address of Plant) | INSPECTOR | ||||||||||||||||

| DATE INSPECTED | |||||||||||||||||

| PLANT OWNED BY (Company or Individual) | INSPECTOR ACCOMPANIED BY (Name and Title) | ||||||||||||||||

| Assigned | Inspr's | Assigned | Inspr's | ||||||||||||||

| SANITARY DEFECTS | Defect | Defect | SANITARY DEFECTS | Defect | Defect | ||||||||||||

| Points | Points | Points | Points | ||||||||||||||

| I. | PREMISES | C. | Toilet room(s) not equipped with self-closing | ||||||||||||||

| A. | Outside premises not well drained. | 3 | doors. | 3 | |||||||||||||

| B. | Outside premises not free of weeds, clutter, | D. | Toilet room(s) open directly into a processing | ||||||||||||||

| or unused equipment or other materials. | 3 | of food storage room where food is exposed. | Critical | ||||||||||||||

| C. | Waste not properly stored or contained. | E. | Cold and hot, water or tepid water not provided | ||||||||||||||

| D. | Outside premises not free of harborage or breeding | 3 | at wash basins. | 3 | |||||||||||||

| places for insects, rodents, birds, or other animals. | F. | Hand cleaner and towels not provided at or | |||||||||||||||

| 4 | near each basin. | 3 | |||||||||||||||

| II. | RAW MATERIALS | G. | Adequate hand-washing signs not posted. | ||||||||||||||

| A. | Beans, peas, and lentils not handled in a | 3 | |||||||||||||||

| sanitary manner that would prevent adulteration. | Critical | H. | Adequate dry waste receptacles not provided. | ||||||||||||||

| 3 | |||||||||||||||||

| III. | CONSTRUCTION OF BUILDING | I. | Toilet facilities not working. | 5 | |||||||||||||

| A. | Plant construction does not exclude probable | J. | Toilet and locker room not satisfactorily | ||||||||||||||

| entrance of insects, rodents, birds or other animals. | 3 | ventilated. | 4 | ||||||||||||||

| B. | Walls, partitions, ceilings, and exposed structural | K. | Toilet and dressing rooms not kept in a clean | ||||||||||||||

| supports in poor repair. | 3 | orderly condition. | 5 | ||||||||||||||

| C. | Floors not smooth and readily cleanable, or | ||||||||||||||||

| impervious under normal usage. | 3 | IX. | CONSTRUCTION AND REPAIR EQUIPMENT | ||||||||||||||

| D. | Floors that frequently get wet not constructed to | A. | Adequate space not allowed around equipment | ||||||||||||||

| prevent pooling or are not kept dry. | 3 | for cleaning and inspection process. | 4 | ||||||||||||||

| E. | Exposed, unprotected overhead sewer lines present | B. | Equipment not designed to protect the product | ||||||||||||||

| in product lines. | Critical | zone against contamination or extraneous | |||||||||||||||

| F. | Walls not sealed at juncture with floor. | material. | 5 | ||||||||||||||

| 3 | C. | Equipment not free of parts or areas | |||||||||||||||

| G. | Walls and ceilings not free of flaked paint, nor in good repair. | inaccessible for cleaning and sanitary | |||||||||||||||

| repair. | 3 | inspection. | 4 | ||||||||||||||

| H. | Windows not intact. | ||||||||||||||||

| I. | Entranceways to production rooms not equipped | 3 | X. | CLEANING AND SANITIZING TREATMENT | |||||||||||||

| with self-closing doors nor provided with other | A. | Equipment not cleaned at frequencies to | |||||||||||||||

| effective means to prevent entrance of vermin. | 3 | prevent contamination of the product. | Critical | ||||||||||||||

| J. | Screen doors, where present, not self closing. | ||||||||||||||||

| 3 | XI. | CONTROL OF INSECTS AND ANIMALS | |||||||||||||||

| IV. | LIGHTING | A. | Presence of evidence of any rodents in plants. | 5 | |||||||||||||

| A. | Production rooms not adequately lighted (20-foot candles). | 3 | B. | Presence of any birds or any other animals | |||||||||||||

| B. | Places where detailed inspection of the product | including domestic types in the plants. | 5 | ||||||||||||||

| or ingredients is required not adequately lighted | C. | Presence of live insects in processing or | |||||||||||||||

| (50-foot candles). | 4 | product storage area (two or more). | Critical | ||||||||||||||

| D. | Presence of dead insects in processing | ||||||||||||||||

| C. | Places where inspection of the processes or | equipment (two or more). | Critical | ||||||||||||||

| operations is required not adequately lighted | E. | Presence of live or dead insects in more than | |||||||||||||||

| (50-foot candles). | 4 | minimal number in other areas (three or more). | 5 | ||||||||||||||

| F. | Rodenticides, insecticides, and other control or | ||||||||||||||||

| D. | Storage areas not adequately lighted (20-foot candles) | 3 | eradication material including applicatory | ||||||||||||||

| E. | Toilets and dressing rooms not adequately lighted | equipment not used in safe acceptable manner. | Critical | ||||||||||||||

| (20-foot candles). | 3 | G. | Evidence that effective pest control not | ||||||||||||||

| F. | Protective shields for lights not present in areas | exercised where needed. | 3 | ||||||||||||||

| where essential to protect the product during protection. | 5 | ||||||||||||||||

| XII. | PERSONNEL | ||||||||||||||||

| V. | VENTILATION | A. | Employees not wearing garments suitable for | ||||||||||||||

| A. | Plant not reasonably free of undesirable odors. | 3 | work being performed. | 4 | |||||||||||||

| B. | Evidence of presence of excessive condensate on | B. | Personnel in contact with unwrapped product or | ||||||||||||||

| walls, ceilings, equipment, or pipeline. | 4 | ingredients not using proper headwear | |||||||||||||||

| C. | Windows opening to the outside not screened with | including protection from facial hair. | 4 | ||||||||||||||

| 14-mesh or finer screen (during presence of flies | C. | Gloves, if worn, not kept in a sanitary condition. | |||||||||||||||

| or other flying insects). | 3 | 3 | |||||||||||||||

| D. | Exhaust fans not screened or equipped with | D. | Storage of employees personal effects in | ||||||||||||||

| self-closing louvers. | 3 | production rooms. | 3 | ||||||||||||||

| E. | Employees not washing hands after | ||||||||||||||||

| VI. | WATER SUPPLY | contamination. | Critical | ||||||||||||||

| A. | Lack of satisfactory evidence that the water supply | F. | Failure of employees to be hygienically clean; | ||||||||||||||

| is potable. | Critical | fingernails not kept cleaned and trimmed. | 4 | ||||||||||||||

| B. | Presence of cross-connection between water | G. | Employees affected with or a carrier of a | ||||||||||||||

| lines and sewage system (not allowed). | communicable or infectious disease not | ||||||||||||||||

| excluded from product areas. | Critical | ||||||||||||||||

| VII. | DISPOSAL OF WASTES | Critical | H. | Plant employees having an infectious wound, | |||||||||||||

| A. | Garbage, trash, and dry waste material, inside | sore, or lesion on hands, arms, or other exposed | |||||||||||||||

| or outside the building, not satisfactorily contained. | 4 | parts of the body, not excluded from contacting | |||||||||||||||

| B. | Waste is not disposed of frequently enough to | ingredients, products or product zone. | 5 | ||||||||||||||

| prevent unsightliness or undesirable odors. | I. | Plant personnel not instructed in acceptable | |||||||||||||||

| 4 | hygienic practices and proper sanitary rules | ||||||||||||||||

| VIII. | TOILET, HAND-WASHING, AND DRESSING ROOM | of food handling. | 5 | ||||||||||||||

| FACILITIES | J. | Personnel not prohibited from expectoring, | |||||||||||||||

| A. | Toilet Facilities not provided for each sex. | 3 | eating, or smoking in product areas. | 5 | |||||||||||||

| B. | Toilets and urinals not water flushed. | ||||||||||||||||

| 3 | TOTAL | …………………………………………………………………………… | |||||||||||||||

| Plant operations are considered to be insanitary if one or more critical defects are found or if the plant receives a score of 46 or higher. | |||||||||||||||||

| Please use reverse side of this form for remarks. | |||||||||||||||||

| FORM FGIS 952-1 (7-02) (Replaces Form FGIS-952-1 (7-91)). Expires January 2015 | |||||||||||||||||

Sheet 2: EXHIBIT

FORM APPROVED OMB NO. 0580-0013: According to the Paperwork Reduction Act of 1995, an agency may not conduct or sponsor, and a person is not required to respond to a collection of information unless it displays a valid OMB control number. The valid OMB control number for this information collection is 00580-0013. The time required is estimated to average 1 hour per response and 1 minute of recordkeeping, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information. |

||||||||||||||||||

| SANITATION INSPECTION REPORT | ||||||||||||||||||

| (BEANS, PEAS, And LENTILS) | ||||||||||||||||||

| SANITATION INSPECTION OF (Name and Address of Plant) | INSPECTOR | |||||||||||||||||

| DATE INSPECTED | ||||||||||||||||||

| PLANT OWNED BY (Company or Individual) | INSPECTOR ACCOMPANIED BY (Name and Title) | |||||||||||||||||

| Assigned | Inspr's | Assigned | Inspr's | |||||||||||||||

| SANITARY DEFECTS | Defect | Defect | SANITARY DEFECTS | Defect | Defect | |||||||||||||

| Points | Points | Points | Points | |||||||||||||||

| I. | PREMISES | C. | Toilet room(s) not equipped with self-closing | |||||||||||||||

| A. | Outside premises not well drained. | 3 | doors. | 3 | ||||||||||||||

| B. | Outside premises not free of weeds, clutter, | D. | Toilet room(s) open directly into a processing | |||||||||||||||

| or unused equipment or other materials. | 3 | of food storage room where food is exposed. | Critical | |||||||||||||||

| C. | Waste not properly stored or contained. | E. | Cold and hot, water or tepid water not provided | |||||||||||||||

| D. | Outside premises not free of harborage or breeding | 3 | at wash basins. | 3 | ||||||||||||||

| places for insects, rodents, birds, or other animals. | F. | Hand cleaner and towels not provided at or | ||||||||||||||||

| 4 | near each basin. | 3 | ||||||||||||||||

| II. | RAW MATERIALS | G. | Adequate hand-washing signs not posted. | |||||||||||||||

| A. | Beans, peas, and lentils not handled in a | 3 | ||||||||||||||||

| sanitary manner that would prevent adulteration. | Critical | H. | Adequate dry waste receptacles not provided. | |||||||||||||||

| 3 | ||||||||||||||||||

| III. | CONSTRUCTION OF BUILDING | I. | Toilet facilities not working. | 5 | ||||||||||||||

| A. | Plant construction does not exclude probable | J. | Toilet and locker room not satisfactorily | |||||||||||||||

| entrance of insects, rodents, birds or other animals. | 3 | ventilated. | 4 | |||||||||||||||

| B. | Walls, partitions, ceilings, and exposed structural | K. | Toilet and dressing rooms not kept in a clean | |||||||||||||||

| supports in poor repair. | 3 | orderly condition. | 5 | |||||||||||||||

| C. | Floors not smooth and readily cleanable, or | |||||||||||||||||

| impervious under normal usage. | 3 | IX. | CONSTRUCTION AND REPAIR EQUIPMENT | |||||||||||||||

| D. | Floors that frequently get wet not constructed to | A. | Adequate space not allowed around equipment | |||||||||||||||

| prevent pooling or are not kept dry. | 3 | for cleaning and inspection process. | 4 | |||||||||||||||

| E. | Exposed, unprotected overhead sewer lines present | B. | Equipment not designed to protect the product | |||||||||||||||

| in product lines. | Critical | zone against contamination or extraneous | ||||||||||||||||

| F. | Walls not sealed at juncture with floor. | material. | 5 | |||||||||||||||

| 3 | C. | Equipment not free of parts or areas | ||||||||||||||||

| G. | Walls and ceilings not free of flaked paint, nor in good repair. | inaccessible for cleaning and sanitary | ||||||||||||||||

| repair. | 3 | inspection. | 4 | |||||||||||||||

| H. | Windows not intact. | |||||||||||||||||

| I. | Entranceways to production rooms not equipped | 3 | X. | CLEANING AND SANITIZING TREATMENT | ||||||||||||||

| with self-closing doors nor provided with other | A. | Equipment not cleaned at frequencies to | ||||||||||||||||

| effective means to prevent entrance of vermin. | 3 | prevent contamination of the product. | Critical | |||||||||||||||

| J. | Screen doors, where present, not self closing. | |||||||||||||||||

| 3 | XI. | CONTROL OF INSECTS AND ANIMALS | ||||||||||||||||

| IV. | LIGHTING | A. | Presence of evidence of any rodents in plants. | 5 | ||||||||||||||

| A. | Production rooms not adequately lighted (20-foot candles). | 3 | B. | Presence of any birds or any other animals | ||||||||||||||

| B. | Places where detailed inspection of the product | including domestic types in the plants. | 5 | |||||||||||||||

| or ingredients is required not adequately lighted | C. | Presence of live insects in processing or | ||||||||||||||||

| (50-foot candles). | 4 | product storage area (two or more). | Critical | |||||||||||||||

| D. | Presence of dead insects in processing | |||||||||||||||||

| C. | Places where inspection of the processes or | equipment (two or more). | Critical | |||||||||||||||

| operations is required not adequately lighted | E. | Presence of live or dead insects in more than | ||||||||||||||||

| (50-foot candles). | 4 | minimal number in other areas (three or more). | 5 | |||||||||||||||

| F. | Rodenticides, insecticides, and other control or | |||||||||||||||||

| D. | Storage areas not adequately lighted (20-foot candles) | 3 | eradication material including applicatory | |||||||||||||||

| E. | Toilets and dressing rooms not adequately lighted | equipment not used in safe acceptable manner. | Critical | |||||||||||||||

| (20-foot candles). | 3 | G. | Evidence that effective pest control not | |||||||||||||||

| F. | Protective shields for lights not present in areas | exercised where needed. | 3 | |||||||||||||||

| where essential to protect the product during protection. | 5 | |||||||||||||||||

| XII. | PERSONNEL | |||||||||||||||||

| V. | VENTILATION | A. | Employees not wearing garments suitable for | |||||||||||||||

| A. | Plant not reasonably free of undesirable odors. | 3 | work being performed. | 4 | ||||||||||||||

| B. | Evidence of presence of excessive condensate on | B. | Personnel in contact with unwrapped product or | |||||||||||||||

| walls, ceilings, equipment, or pipeline. | 4 | ingredients not using proper headwear | ||||||||||||||||

| C. | Windows opening to the outside not screened with | including protection from facial hair. | 4 | |||||||||||||||

| 14-mesh or finer screen (during presence of flies | C. | Gloves, if worn, not kept in a sanitary condition. | ||||||||||||||||

| or other flying insects). | 3 | 3 | ||||||||||||||||

| D. | Exhaust fans not screened or equipped with | D. | Storage of employees personal effects in | |||||||||||||||

| self-closing louvers. | 3 | production rooms. | 3 | |||||||||||||||

| E. | Employees not washing hands after | |||||||||||||||||

| VI. | WATER SUPPLY | contamination. | Critical | |||||||||||||||

| A. | Lack of satisfactory evidence that the water supply | F. | Failure of employees to be hygienically clean; | |||||||||||||||

| is potable. | Critical | fingernails not kept cleaned and trimmed. | 4 | |||||||||||||||

| B. | Presence of cross-connection between water | G. | Employees affected with or a carrier of a | |||||||||||||||

| lines and sewage system (not allowed). | communicable or infectious disease not | |||||||||||||||||

| excluded from product areas. | Critical | |||||||||||||||||

| VII. | DISPOSAL OF WASTES | Critical | H. | Plant employees having an infectious wound, | ||||||||||||||

| A. | Garbage, trash, and dry waste material, inside | sore, or lesion on hands, arms, or other exposed | ||||||||||||||||

| or outside the building, not satisfactorily contained. | 4 | parts of the body, not excluded from contacting | ||||||||||||||||

| B. | Waste is not disposed of frequently enough to | ingredients, products or product zone. | 5 | |||||||||||||||

| prevent unsightliness or undesirable odors. | I. | Plant personnel not instructed in acceptable | ||||||||||||||||

| 4 | hygienic practices and proper sanitary rules | |||||||||||||||||

| VIII. | TOILET, HAND-WASHING, AND DRESSING ROOM | of food handling. | 5 | |||||||||||||||

| FACILITIES | J. | Personnel not prohibited from expectoring, | ||||||||||||||||

| A. | Toilet Facilities not provided for each sex. | 3 | eating, or smoking in product areas. | 5 | ||||||||||||||

| B. | Toilets and urinals not water flushed. | |||||||||||||||||

| 3 | TOTAL | …………………………………………………………………………… | ||||||||||||||||

| Plant operations are considered to be insanitary if one or more critical defects are found or if the plant receives a score of 46 or higher. | ||||||||||||||||||

| Please use reverse side of this form for remarks. | ||||||||||||||||||

| FORM FGIS 952-1 (7-02) (Replaces Form FGIS-952-1 (7-91)) | ||||||||||||||||||

Sheet 3: INSTRUCTIONS

| SANITATION INSPECTION REPORT (SIR) | |||||||||||||

| FGIS‑952‑1, For Beans, Peas, and Lentils Processors | |||||||||||||

| 1. Name of plant and physical address of the sanitation inspection. | |||||||||||||

| 2. Name of the company or individual that owns the plant. | |||||||||||||

| 3. Name of the inspector performing the inspection. | |||||||||||||

| 4. Date of inspection. | |||||||||||||

| 5. Name and title of plant personnel that accompanied the inspector during the inspection. | |||||||||||||

| 6. Assigned Defect Points. This column contains pre-assigned individual defect points. The range of points assigned is based on the importance of the defect item to the maintenance of good sanitation in the plant. For example, the defect item "Presence or evidence of rodents in plant," is assigned a point range of 0 to 5; whereas, "Waste not properly stored or contained," is assigned a point range of 0 to 3. The most serious defects do not have assigned defect points but are listed as "critical.” | |||||||||||||

| 7. Inspector’s Defect Points. In this column rate the individual defect item based on your opinion as to the relative potential for product contamination. If the item is clean and presents no sanitation problem, assign 0 defect points to the item. If the item is relatively clean but not perfect, assign 1 or 2 defect points to the item. If the item is insanitary or presents a clear hazard to sanitary operations, assign the maximum defect points possible for that item. Score critical Items as either "pass" or "fail." For example, the item "Presence of live insects in processing or product storage areas (two or more)" is a critical item. When any type of insect is present in the number indicated, it is a critical defect. Use the back of the form for remarks and explain critical defects to clearly describe the conditions observed. | |||||||||||||

| 8. Total the Inspector’s Defect Points. If the SIR score meets or exceeds 46, consider plant operations insanitary. A plant may not have any critical items but their overall sanitary condition is so poor that they should discontinue processing and have a general cleanup or initiate a maintenance program. Evaluate plants in this condition based on their total SIR score. | |||||||||||||

| 9. Place any remarks on the back of the form. | |||||||||||||

| Immediately after completing the SIR, give a copy to the plant representative. This copy is the plant's written notification of the conditions found. | |||||||||||||

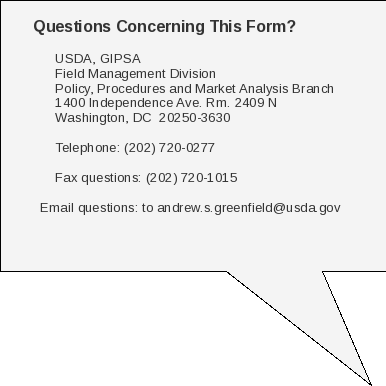

Sheet 4: CONTACT

|

|||||||

|

|||||||

| File Type | application/vnd.ms-excel |

| File Title | SANITATION INSPECTION REPORT (BEANS, PEAS, AND LENTILS) |

| Author | USDA GIPSA FGIS |

| Last Modified By | ASGreenfield |

| File Modified | 2011-04-22 |

| File Created | 2002-06-06 |

© 2025 OMB.report | Privacy Policy